Originally Posted By: DiRTY DOG

Brass/primers

Case mouths, 2x fired brass, annealed every reload.

From the above pics.

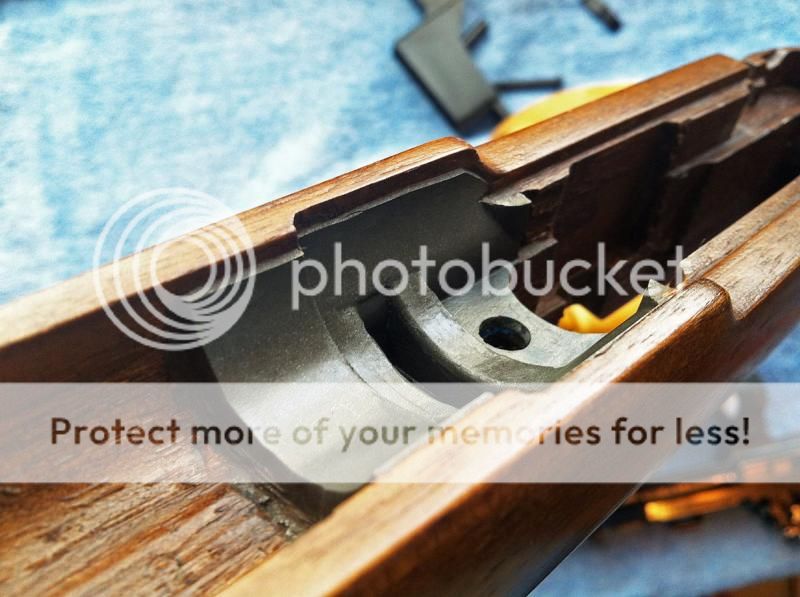

1. I personally don't buy into the bedding of the first inch of barrel theory. The only barrels that can actually be called free floated are those with nothing touching them anywhere including the first inch infront of the lug. I would remove the bedding infront of the lug so nothing at all was touching the barrel itself. You would be amazed at the difference it can make. I have a Cooper Pheonix in 6mm i purchased used. I wouldnt shoot at all, it showed some promise but no consistency what so ever. I took it to a wise old gun smith who told me to put it in his mill and remove Coopers bedding infront of the lug and go shoot it again. I did and with that being the only change I made, that rifle shot 5 different test loads using two different bullets under 3/4 MOA the very next trip to the range. It will shoot about anything I feed it now. It won't do much for your keyhole problem but I bet your consistency and over all accuracy improves.

Also,

The gap between the barrel and stock looks nice but did you create it with bedding the action up or did you open the channel in the stock by sanding? My only CZ doesn't have clearance like that and I don't recall seeing one with quite as much without extra work, IDK...

2. Anyone else notice the line above the web of the brass? It's common but yours looks a bit extreme. Looks like your about to separate cases. Could be over sizing.

3. Case mouth looks rolled in. Are you attempting to crimp? I would back off the seater die and remove any and all crimp created by it, you shouldn't need it. That little bit could deform the already small and delicate bullet causing problems.

Stop annealing after every firing, it's unnecessary. I would also clean that rifle until the patches came out as clean as they go in. Pay special attention to the chamber end and the first few inches of barrel.

I'd like to see a spotless bore, no bedding infront of the lug and pictures of a target and brass from a box of factory ammo fired thru the rifle, no reloads of any kind.