Originally Posted By: msinc

Bottom line, what I am seeing and testing just doesn't support all this exact science, certain exact absolute temperature, heat time just right, "rocket science" quench in magic voodoo liquid to get brass cases dead soft.

Heat 'em till they just start to glow, drop 'em in the water and go shooting.

If you guys read nothing else about handloading today (this week, this month, this year), read the above sentence again... three times - it should be cut in stone!

I have been annealing since the mid 60's (1960's that is

).

I started with the accepted "pan & Water" and soon discovered that the water made no difference. I learned from an old timer that the cases had to be spun so the annealing would be uniform all around. He did them on a small lathe and torch. I went to a 1/4" drill and wrench socket.

I tried an expensive machine at one point, but found that it took too much time to set up and adjust because different sized cases require different annealing times (by a LOT), it took up too much space, and was actually slower than doing it with a drill and wrench socket. When Hornady came out with their aluminum kit for power screw drivers, I snapped one up and never looked back.

Some people will tell you that if you see "yellow" you have ruined the cases - pure unadulterated bullpoopie - the yellow flame color is from ionized carbon. (remember your 10th grade chemistry class)

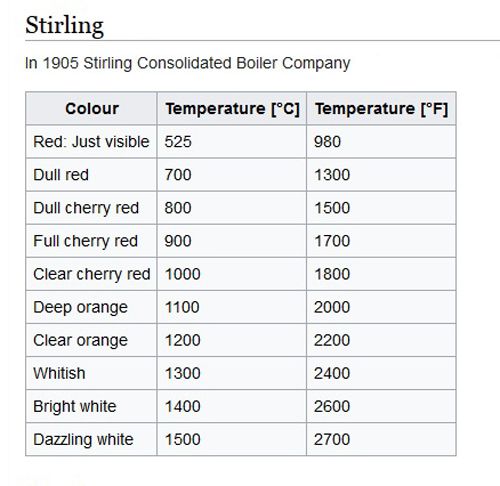

Copper, Zinc and Tin, when heated enough, all make green flames, NOT yellow... and you can NOT get a brass case neck hot enough with a propane torch to get to the green flame temperature zone. It is impossible!

Sometimes, annealing new cases will show yellow in the flame. It is because new cases often have wax/polish on them from the factory that will show yellow in a propane torch.

Below are two sets of brass cases. Both sets are BRAND NEW Remington brand, 6mm Rem (244) cases - the three on the left are right out of the box. The three on the right have been washed in liquid Tide clothing detergent (boiled for several minutes) and then completely rinsed, and air dried. All six were annealed at the same time, at the same temperature, for the same period of time.

The difference in colours are due to:

1 - The cases on the left had factory wax/polish which oxidized.

2 - the cases on the right shows the true color of annealed brass alone, without any chemicals adding to the oxidation process.

You cannot anneal by time - my 223 requires 1/4th the time in the flame as does my 300 Win Mag.

I heat the case to a dark cherry red and keep it there for 3 to 4 seconds, and then drop it on a crumpled piece of aluminum foil. I do not use any water.

When they cool off, I stack them...

I anneal between 2,000 and 4,000 cases a year, and have been doing it for 50+ years, and I have NEVER ruined a case.

There is no magic mumbo jumbo to annealing - it is easy peasy!