WhoCares

New member

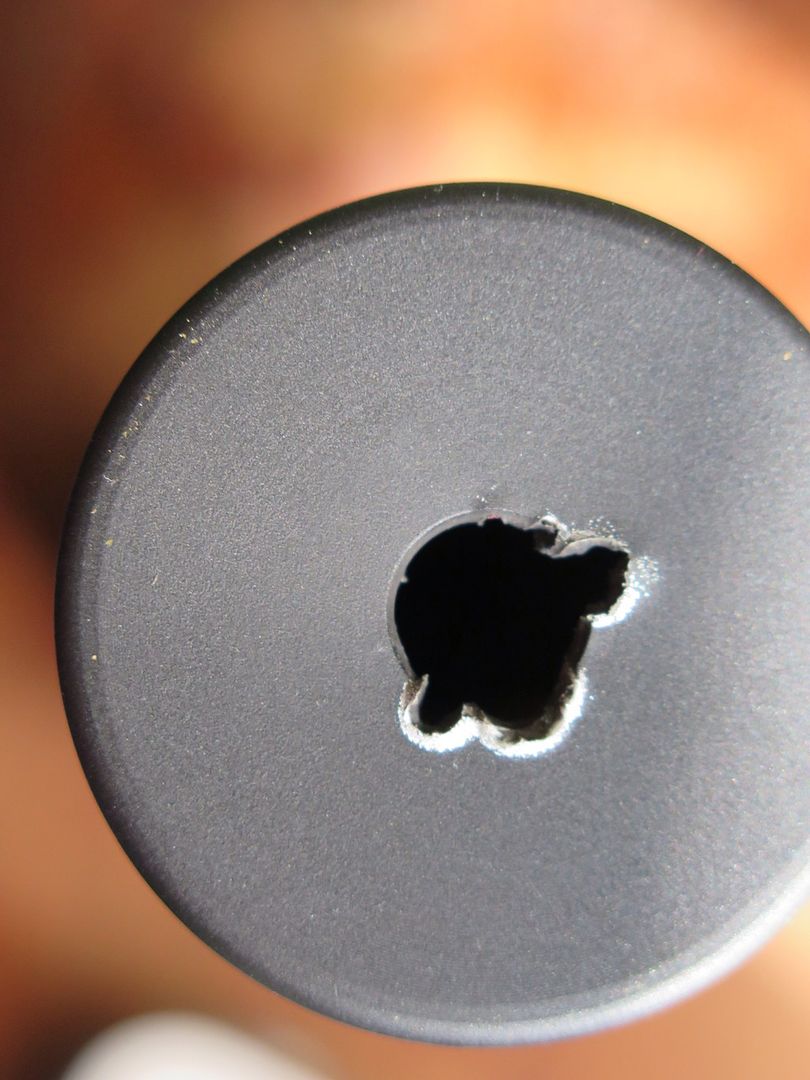

I just got my first suppressor recently. A Griffin DT Model. First time at the range and I shot the end of the can up. Hole on the exit end looked like a clover leaf. Sent it back and they said the can fit on their fixture perfectly so it had to be that I did not tighten it properly on my barrel. They said that the can had rotated 180 degrees during firing and that is what caused the damage. Weird thing was, is that it was just as tight after firing as it was before I shot it. They also said thats why they make a quick detach model. They said the QD uses a torqued part on the barrel so when u screw on the suppressor it is always aligned and torqued properly. Going to cost me $200 to fix a new suppressor.

I hand tightened the can as tight as I possibly could without using tools. I only fired 10 rounds before I figured out something was wrong. I could not get on paper and the shots were all over the place. Anyway just to be safe I sent all my threaded barrels back to Mike at DTech to have them checked and re-threaded if necessary

Anyone ever had this happen to them with a Direct Thread suppressor.

I hand tightened the can as tight as I possibly could without using tools. I only fired 10 rounds before I figured out something was wrong. I could not get on paper and the shots were all over the place. Anyway just to be safe I sent all my threaded barrels back to Mike at DTech to have them checked and re-threaded if necessary

Anyone ever had this happen to them with a Direct Thread suppressor.