Thanks Bob appreciate your reply. I will explain some more about what I'm working on.

First I pattern tested some loads at 40, 50 & 60 yards and found lead BB held a good pattern, my home loads put 6 pellets in a fox size target at 60 yards. This is repeatable with some shots putting 10 pellets into the target.

When I move back to 75 yards the BB pattern is not so good and I noticed pellets where not going through the plywood target board. The next size pellet I tried was 4 Buck and that makes a decent pattern with plenty of energy for a fox however I would like more pellets in my 12 gauge 3" 1.5oz load. Thus the question about T Buck.

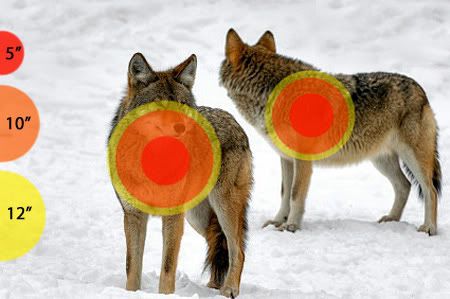

I note your last para and fully agree. My longest shot on a fox was 50-55 yards. I'm working on a project to see if I can produce a killing pattern out to 75 yards and that means consistently putting 6 hits into a fox's head/vitals.

I am in no way suggesting anyone tries shooting live fox/coyote at this range. It is my own research into what a shotgun can do with hand loads and optimizing pattern results using screw in chokes tuned to the load.

To many people over here think buckshot covers a barn door at 10 yards, so it surprised a few when I posted a fox target with 8 00 Buck holes in it shot at 40 yards, 100% of the payload.

Thanks again.

First I pattern tested some loads at 40, 50 & 60 yards and found lead BB held a good pattern, my home loads put 6 pellets in a fox size target at 60 yards. This is repeatable with some shots putting 10 pellets into the target.

When I move back to 75 yards the BB pattern is not so good and I noticed pellets where not going through the plywood target board. The next size pellet I tried was 4 Buck and that makes a decent pattern with plenty of energy for a fox however I would like more pellets in my 12 gauge 3" 1.5oz load. Thus the question about T Buck.

I note your last para and fully agree. My longest shot on a fox was 50-55 yards. I'm working on a project to see if I can produce a killing pattern out to 75 yards and that means consistently putting 6 hits into a fox's head/vitals.

I am in no way suggesting anyone tries shooting live fox/coyote at this range. It is my own research into what a shotgun can do with hand loads and optimizing pattern results using screw in chokes tuned to the load.

To many people over here think buckshot covers a barn door at 10 yards, so it surprised a few when I posted a fox target with 8 00 Buck holes in it shot at 40 yards, 100% of the payload.

Thanks again.