You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

purpose of cotton in brass after powder

- Thread starter predyotevarmint

- Start date

SShooterZ

New member

Originally Posted By: CatShooterWhy do you guys make this stuff up - it is mind boggling.

Sorry, I was just trying to make an analogy that I thought some people might relate to. (And I failed miserably it seems.) And then we go down the path of burning wood characteristics. SMH!

Sorry, I was just trying to make an analogy that I thought some people might relate to. (And I failed miserably it seems.) And then we go down the path of burning wood characteristics. SMH!

2muchgun

New member

Originally Posted By: Rocky1Too much database garbage in the link for the database here to translate it, punctuation marks tend to confuse translation of links, although all databases use them. Have to go to Full Reply Screen and build a link out of the link 2MG...

Absolute Chamber Pressure in Centerfire Rifles

Thanks. It was late and that was more effort than I cared to put in at the time

Absolute Chamber Pressure in Centerfire Rifles

Thanks. It was late and that was more effort than I cared to put in at the time

Raymond Blaker

New member

Nitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

Originally Posted By: Raymond BlakerNitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

Every kernel of powder is ignited at once. They do burn at different rates...hence burn rates....but every kernel in the case starts at once. Black powder is the same way, and also has different burn rates. Equating sugar and flour to gun powder is silly, at best.

Black powder and smokeless are different class explosives due to how they can be ignited. You can pop off a pile of BP with a sledge hammer...not so much with smokeless. That's what they have different handling procedures, hence the different classification.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

Every kernel of powder is ignited at once. They do burn at different rates...hence burn rates....but every kernel in the case starts at once. Black powder is the same way, and also has different burn rates. Equating sugar and flour to gun powder is silly, at best.

Black powder and smokeless are different class explosives due to how they can be ignited. You can pop off a pile of BP with a sledge hammer...not so much with smokeless. That's what they have different handling procedures, hence the different classification.

CatShooter

New member

Originally Posted By: Raymond Blaker

Nitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

This keeps getting dumber and dumber. Do you know what the burn rates are - I think not, based on your examples.

Black powder does not burn all at once - the burning rate for black powder is 96 inches per second - which means if you have a solid stick of black powder that is 96 inches long, it will take one second to burn if you light it at one end.

If you have a round ball of black powder that is 2 times 96 inches in diameter, and light it on all sides at one, it will take one second to burn.

If you have a grain of black powder that is 1/1,000 that size (0.096") it will burn in 1/1,000th of a second. One forth that size (0.024") will burn in 1/4,000 of a second.. and so on.

It makes no difference what the pressure is, black powder burns at a constant speed.

The black powder burns ON the surface of the grain - the "flame" is actually part of the surface, which is why the burning speed is constant.

Smokeless powder does NOT burn at a fixed speed, and technically, it does not burn at all - it "Deflagerates".

It goes through a two stage decomposition process. The grains are heated and put under pressure by the primer. The grain surface first melts, and then breaks down to several very large, complex molecule, gases which are given off from the melted surface - it is these gases that create the flame as they devolve into new, simpler gases that take up more space and generate more heat because of the broken carbon bonds.

In the open air, a pile of 4895 can take 5 or more seconds to burn. There is no "flash-over". You light the pile at one end, and it burns slowly across the pile.

Smokeless powder is totally dependent of the pressure it is burning in - the higher the pressure, the faster it burns... which (for those that live in Rio Linda), is why it is called "progressive" burning powder. The "Speed" rating of smokeless powder are done under high pressure, and are relative to each other, not specific like black powder.

In a cartridge case, the primer heats the whole interior of the case and puts the powder under fairly high pressure. The powder grains light at the same time - the burning is NOT from one end to the other. Then the nitrocellulose starts it's two stage burning process.

As the pressure builds, the flame front gets pushed closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so the more gas is given off, which makes the pressures higher, which pushes the flame front closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so more gas is given off, which makes the pressures higher, which... on and on.

If the pressure drops before the grains are finished burning (the bullet leaves the barrel), the flame moves away from the surface of the grain, so the heat drops, so the grain gives off less gas, which causes the flame to move further away from the grain, and the whole thing is reversed - until the "fire" goes out and the remaining piece of the grain is left in the case, or barrel, or on the ground - unburned.

And THAT is why you will find unburned powder in barrels or cases.

I once witnessed a 45-70 being fired with a full case of 3031, and a 200gr lead pistol bullet - there was practicably no resistance for the bullet and it slipped out of the barrel like a piece of owl poop.

When the case was removed, a "solid" thing fell out of the case that looked like a cigar ash - it was a solid lump of 3031, where all the grains started to burn from the primer, and the grain surface started to melt, but there was not enough pressure to keep the flame going and it simply "went out", and all the grains fused together when it cooled.

I offered the guy $10 for the fused lump of powder, but he decided to light it with a match instead.

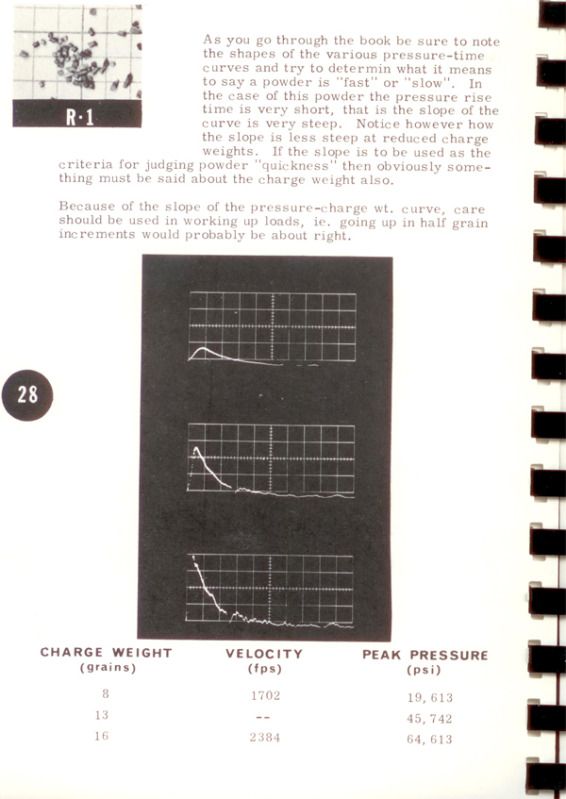

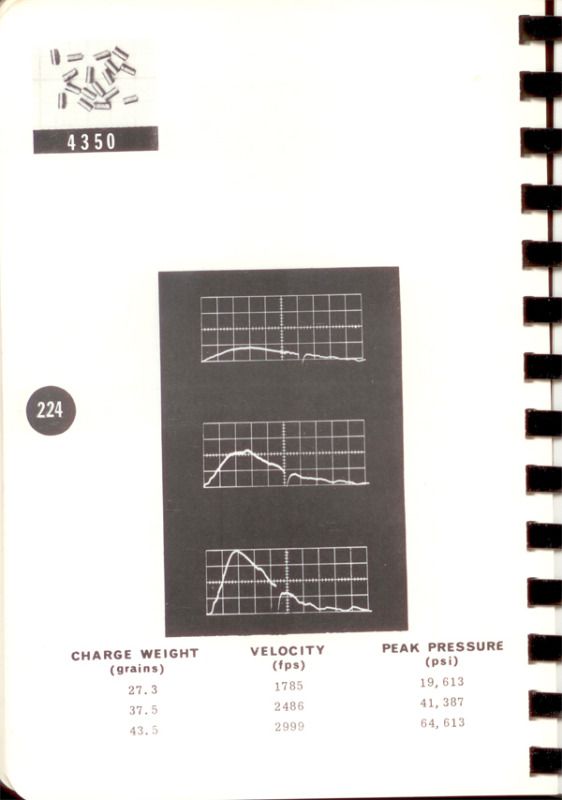

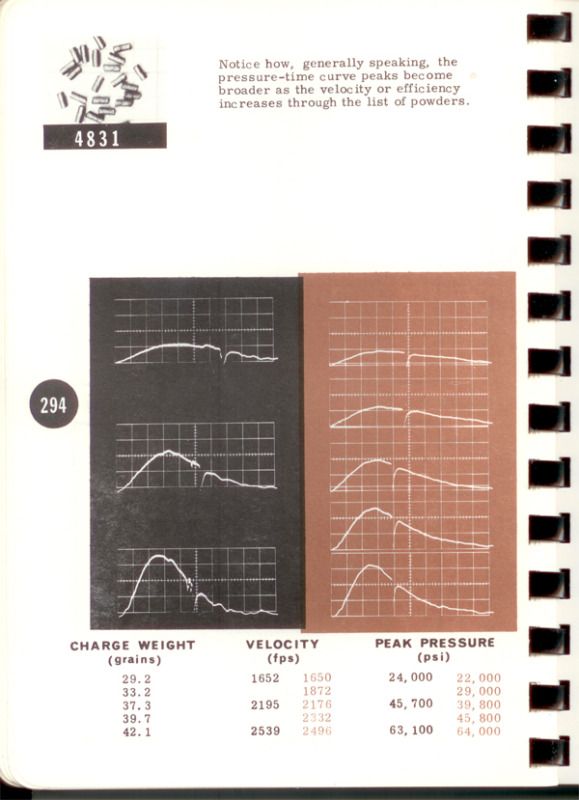

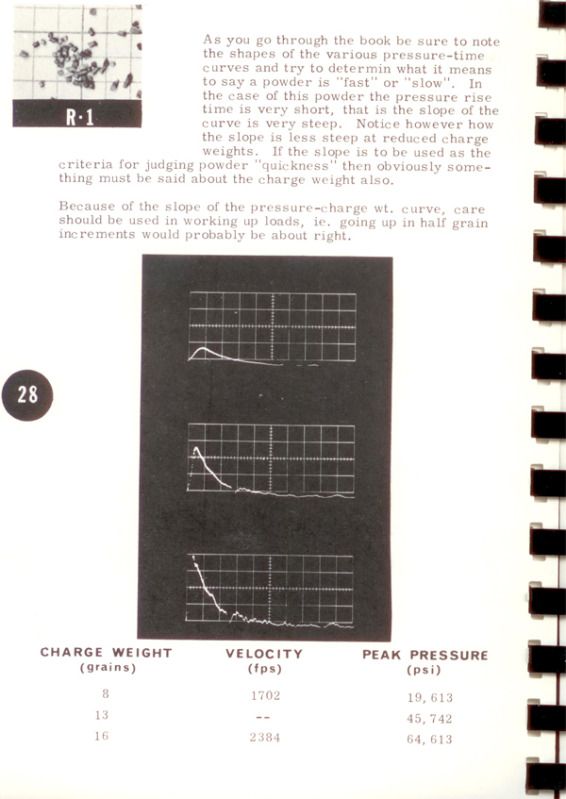

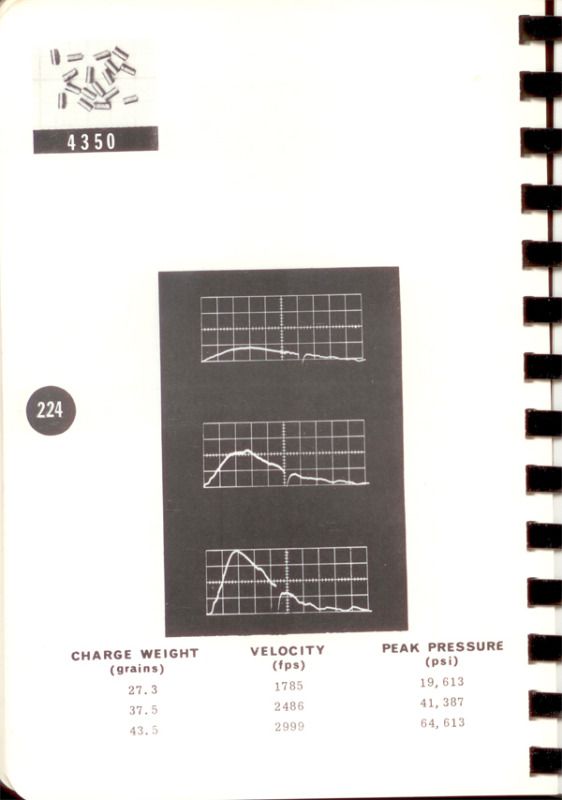

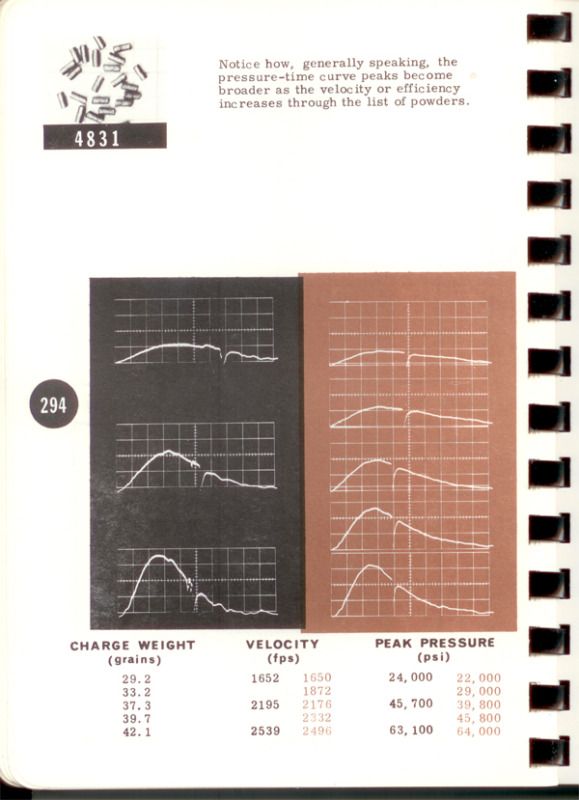

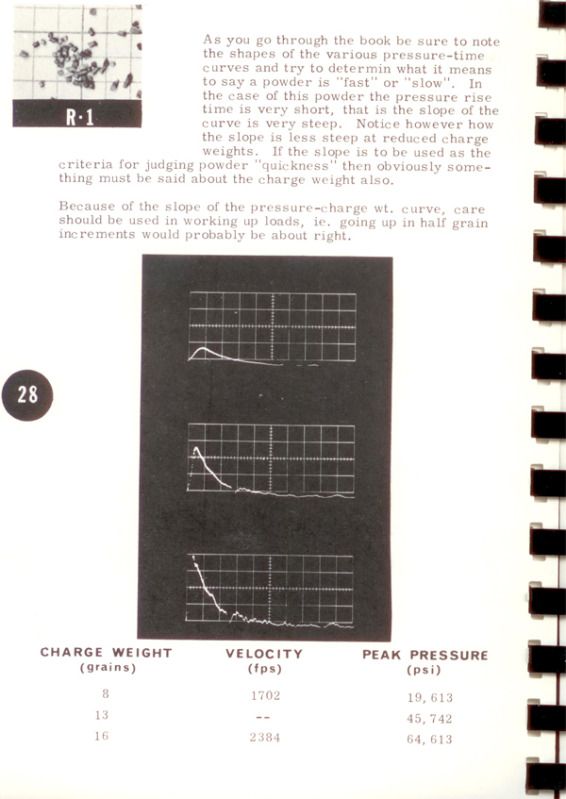

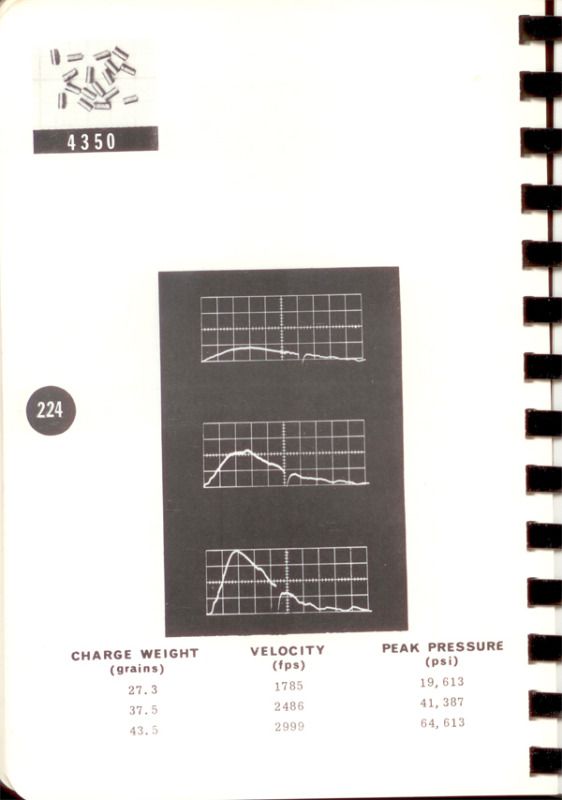

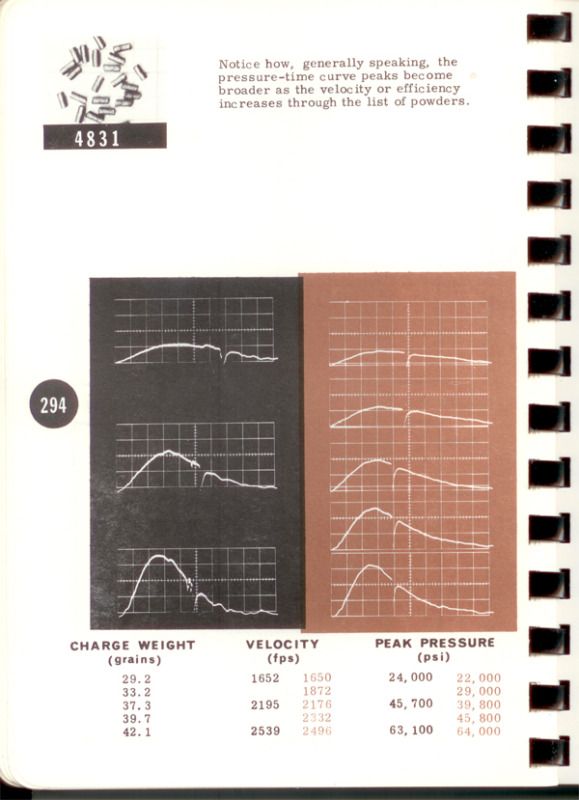

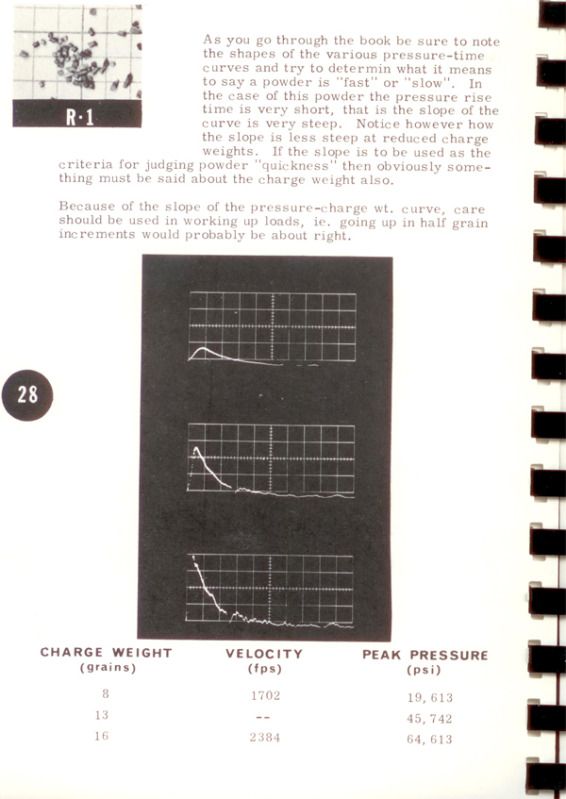

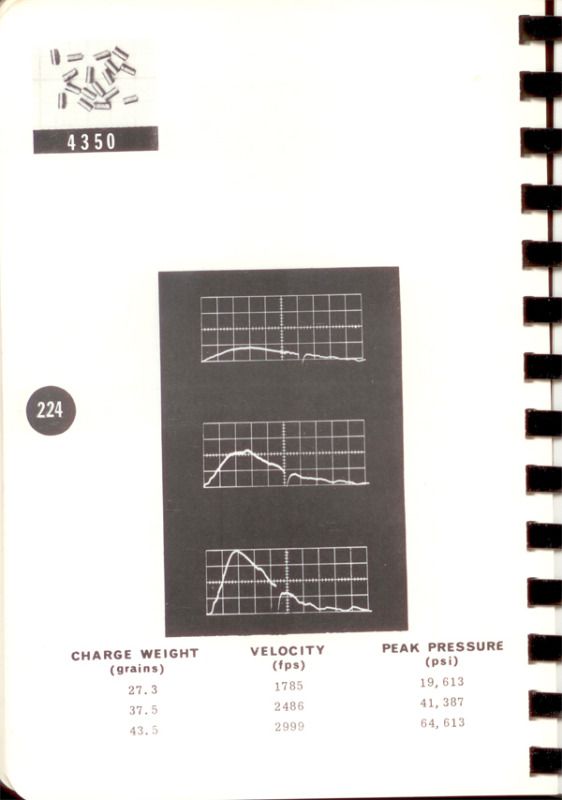

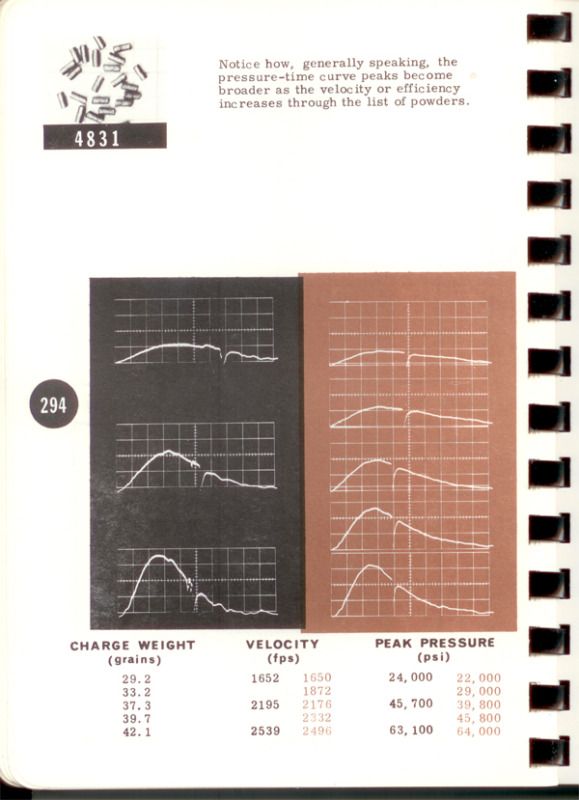

Back in 1978, I bought an interesting book.

The authors took the 243 and the 6mm Rem, and loaded EVERY powder available, from the fastest pistol, to the slowest machine gun powder, and used a strain gauge (very new at the time) to measure the pressures and plot the pressure curves. It was way before it's time, and I think even now, it is still before it's time.

But, with the prior comments about "flash over" and pressure problems with large space in a case, I thought these curves might throw some light (and truth) on the subject.

If you look carefully at the curves, you can see that they are predictable.

So - it should be obvious that "flash over" is impossible, and all these analogies about sawdust and other stuff, is pure garbage and fabrications.

As far as throwing dust in an open fire?? Do you really want us to take you seriously??

Please give us a break from silliness!!

.

Nitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

This keeps getting dumber and dumber. Do you know what the burn rates are - I think not, based on your examples.

Black powder does not burn all at once - the burning rate for black powder is 96 inches per second - which means if you have a solid stick of black powder that is 96 inches long, it will take one second to burn if you light it at one end.

If you have a round ball of black powder that is 2 times 96 inches in diameter, and light it on all sides at one, it will take one second to burn.

If you have a grain of black powder that is 1/1,000 that size (0.096") it will burn in 1/1,000th of a second. One forth that size (0.024") will burn in 1/4,000 of a second.. and so on.

It makes no difference what the pressure is, black powder burns at a constant speed.

The black powder burns ON the surface of the grain - the "flame" is actually part of the surface, which is why the burning speed is constant.

Smokeless powder does NOT burn at a fixed speed, and technically, it does not burn at all - it "Deflagerates".

It goes through a two stage decomposition process. The grains are heated and put under pressure by the primer. The grain surface first melts, and then breaks down to several very large, complex molecule, gases which are given off from the melted surface - it is these gases that create the flame as they devolve into new, simpler gases that take up more space and generate more heat because of the broken carbon bonds.

In the open air, a pile of 4895 can take 5 or more seconds to burn. There is no "flash-over". You light the pile at one end, and it burns slowly across the pile.

Smokeless powder is totally dependent of the pressure it is burning in - the higher the pressure, the faster it burns... which (for those that live in Rio Linda), is why it is called "progressive" burning powder. The "Speed" rating of smokeless powder are done under high pressure, and are relative to each other, not specific like black powder.

In a cartridge case, the primer heats the whole interior of the case and puts the powder under fairly high pressure. The powder grains light at the same time - the burning is NOT from one end to the other. Then the nitrocellulose starts it's two stage burning process.

As the pressure builds, the flame front gets pushed closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so the more gas is given off, which makes the pressures higher, which pushes the flame front closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so more gas is given off, which makes the pressures higher, which... on and on.

If the pressure drops before the grains are finished burning (the bullet leaves the barrel), the flame moves away from the surface of the grain, so the heat drops, so the grain gives off less gas, which causes the flame to move further away from the grain, and the whole thing is reversed - until the "fire" goes out and the remaining piece of the grain is left in the case, or barrel, or on the ground - unburned.

And THAT is why you will find unburned powder in barrels or cases.

I once witnessed a 45-70 being fired with a full case of 3031, and a 200gr lead pistol bullet - there was practicably no resistance for the bullet and it slipped out of the barrel like a piece of owl poop.

When the case was removed, a "solid" thing fell out of the case that looked like a cigar ash - it was a solid lump of 3031, where all the grains started to burn from the primer, and the grain surface started to melt, but there was not enough pressure to keep the flame going and it simply "went out", and all the grains fused together when it cooled.

I offered the guy $10 for the fused lump of powder, but he decided to light it with a match instead.

Back in 1978, I bought an interesting book.

The authors took the 243 and the 6mm Rem, and loaded EVERY powder available, from the fastest pistol, to the slowest machine gun powder, and used a strain gauge (very new at the time) to measure the pressures and plot the pressure curves. It was way before it's time, and I think even now, it is still before it's time.

But, with the prior comments about "flash over" and pressure problems with large space in a case, I thought these curves might throw some light (and truth) on the subject.

If you look carefully at the curves, you can see that they are predictable.

So - it should be obvious that "flash over" is impossible, and all these analogies about sawdust and other stuff, is pure garbage and fabrications.

As far as throwing dust in an open fire?? Do you really want us to take you seriously??

Please give us a break from silliness!!

.

tactical assault

New member

Originally Posted By: SShooterZSo what you're saying is use the cotton right?

NO, you missed the point again. You only use the cotton in the .223 cases, because it will flash over in the 5.56 cases. Don't worry, we will get you through it brother!!!

NO, you missed the point again. You only use the cotton in the .223 cases, because it will flash over in the 5.56 cases. Don't worry, we will get you through it brother!!!

BroncoGlenn

New member

Originally Posted By: CatShooterOriginally Posted By: Raymond Blaker

Nitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

This keeps getting dumber and dumber. Do you know what the burn rates are - I think not, based on your examples.

.

Fooey on your science and relevant supporting documentation! Don't you know that there's no room for that in the speculation, conjuration, conjecture, presumption, supposition and postulation based on erroneous information?

Nitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

This keeps getting dumber and dumber. Do you know what the burn rates are - I think not, based on your examples.

.

Fooey on your science and relevant supporting documentation! Don't you know that there's no room for that in the speculation, conjuration, conjecture, presumption, supposition and postulation based on erroneous information?

Bullmastiff

New member

Originally Posted By: CatShooterOriginally Posted By: Raymond Blaker

Nitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

This keeps getting dumber and dumber. Do you know what the burn rates are - I think not, based on your examples.

Black powder does not burn all at once - the burning rate for black powder is 96 inches per second - which means if you have a solid stick of black powder that is 96 feet long, it will take one second to burn if you light it at one end.

If you have a round ball of black powder that is 2 times 96 inches in diameter, and light it on all sides at one, it will take one second to burn.

If you have a grain of black powder that is 1/1,000 that size (0.096") it will burn in 1/1,000th of a second. One forth that size (0.024") will burn in 1/4,000 of a second.. and so on.

It makes no difference what the pressure is, black powder burns at a constant speed.

The black powder burns ON the surface of the grain - the "flame" is actually part of the surface, which is why the burning speed is constant.

Smokeless powder does NOT burn at a fixed speed, and technically, it does not burn at all - it "Deflagerates".

It goes through a two stage decomposition process. The grains are heated and put under pressure by the primer. The grain surface first melts, and then breaks down to several very large, complex molecule, gases which are given off from the melted surface - it is these gases that create the flame as they devolve into new, simpler gases that take up more space and generate more heat because of the broken carbon bonds.

In the open air, a pile of 4895 can take 5 or more seconds to burn. There is no "flash-over". You light the pile at one end, and it burns slowly across the pile.

Smokeless powder is totally dependent of the pressure it is burning in - the higher the pressure, the faster it burns... which (for those that live in Rio Linda), is why it is called "progressive" burning powder. The "Speed" rating of smokeless powder are done under high pressure, and are relative to each other, not specific like black powder.

In a cartridge case, the primer heats the whole interior of the case and puts the powder under fairly high pressure. The powder grains light at the same time - the burning is NOT from one end to the other. Then the nitrocellulose starts it's two stage burning process.

As the pressure builds, the flame front gets pushed closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so the more gas is given off, which makes the pressures higher, which pushes the flame front closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so more gas is given off, which makes the pressures higher, which... on and on.

If the pressure drops before the grains are finished burning (the bullet leaves the barrel), the flame moves away from the surface of the grain, so the heat drops, so the grain gives off less gas, which causes the flame to move further away from the grain, and the whole thing is reversed - until the "fire" goes out and the remaining piece of the grain is left in the case, or barrel, or on the ground - unburned.

And THAT is why you will find unburned powder in barrels or cases.

I once witnessed a 45-70 being fired with a full case of 3031, and a 200gr lead pistol bullet - there was practicably no resistance for the bullet and it slipped out of the barrel like a piece of owl poop.

When the case was removed, a "solid" thing fell out of the case that looked like a cigar ash - it was a solid lump of 3031, where all the grains started to burn from the primer, and the grain surface started to melt, but there was not enough pressure to keep the flame going and it simply "went out", and all the grains fused together when it cooled.

I offered the guy $10 for the fused lump of powder, but he decided to light it with a match instead.

Back in 1978, I bought an interesting book.

The authors took the 243 and the 6mm Rem, and loaded EVERY powder available, from the fastest pistol, to the slowest machine gun powder, and used a strain gauge (very new at the time) to measure the pressures and plot the pressure curves. It was way before it's time, and I think even now, it is still before it's time.

But, with the prior comments about "flash over" and pressure problems with large space in a case, I thought these curves might throw some light (and truth) on the subject.

If you look carefully at the curves, you can see that they are predictable.

So - it should be obvious that "flash over" is impossible, and all these analogies about sawdust and other stuff, is pure garbage and fabrications.

As far as throwing dust in an open fire?? Do you really want us to take you seriously??

Please give us a break from silliness!!

.

OK, so I have an applied fluid mechanics project to finish and final to prepare for, so I thought I would take a break and relax my brain a little on Predator Master's and I ran into Catshooter spanking somebody with facts that made my brain hurt more. I'm going back to Manning's equation, critical flow and hydraulic jump, at least I understand that.

Nitro powder doesn't ignite all at ones, but burns at controlled rates depending on the powder type. Black powder ignites all at once and is hence a class one explosive, whereas nitro powder is a class 6 explosive.

Check your powder burn rates, another example, take sugar, flour, or even metal shavings and chuck it balled into a fire, it will burn but slowly, now throw it into the fire as a dust, and it will explode, same thing will happen of you have a reduced powder load where the primer goes over the lot in one go.

This keeps getting dumber and dumber. Do you know what the burn rates are - I think not, based on your examples.

Black powder does not burn all at once - the burning rate for black powder is 96 inches per second - which means if you have a solid stick of black powder that is 96 feet long, it will take one second to burn if you light it at one end.

If you have a round ball of black powder that is 2 times 96 inches in diameter, and light it on all sides at one, it will take one second to burn.

If you have a grain of black powder that is 1/1,000 that size (0.096") it will burn in 1/1,000th of a second. One forth that size (0.024") will burn in 1/4,000 of a second.. and so on.

It makes no difference what the pressure is, black powder burns at a constant speed.

The black powder burns ON the surface of the grain - the "flame" is actually part of the surface, which is why the burning speed is constant.

Smokeless powder does NOT burn at a fixed speed, and technically, it does not burn at all - it "Deflagerates".

It goes through a two stage decomposition process. The grains are heated and put under pressure by the primer. The grain surface first melts, and then breaks down to several very large, complex molecule, gases which are given off from the melted surface - it is these gases that create the flame as they devolve into new, simpler gases that take up more space and generate more heat because of the broken carbon bonds.

In the open air, a pile of 4895 can take 5 or more seconds to burn. There is no "flash-over". You light the pile at one end, and it burns slowly across the pile.

Smokeless powder is totally dependent of the pressure it is burning in - the higher the pressure, the faster it burns... which (for those that live in Rio Linda), is why it is called "progressive" burning powder. The "Speed" rating of smokeless powder are done under high pressure, and are relative to each other, not specific like black powder.

In a cartridge case, the primer heats the whole interior of the case and puts the powder under fairly high pressure. The powder grains light at the same time - the burning is NOT from one end to the other. Then the nitrocellulose starts it's two stage burning process.

As the pressure builds, the flame front gets pushed closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so the more gas is given off, which makes the pressures higher, which pushes the flame front closer to the surface of the grain - the closer it gets, the hotter the surface of the grain gets, so more gas is given off, which makes the pressures higher, which... on and on.

If the pressure drops before the grains are finished burning (the bullet leaves the barrel), the flame moves away from the surface of the grain, so the heat drops, so the grain gives off less gas, which causes the flame to move further away from the grain, and the whole thing is reversed - until the "fire" goes out and the remaining piece of the grain is left in the case, or barrel, or on the ground - unburned.

And THAT is why you will find unburned powder in barrels or cases.

I once witnessed a 45-70 being fired with a full case of 3031, and a 200gr lead pistol bullet - there was practicably no resistance for the bullet and it slipped out of the barrel like a piece of owl poop.

When the case was removed, a "solid" thing fell out of the case that looked like a cigar ash - it was a solid lump of 3031, where all the grains started to burn from the primer, and the grain surface started to melt, but there was not enough pressure to keep the flame going and it simply "went out", and all the grains fused together when it cooled.

I offered the guy $10 for the fused lump of powder, but he decided to light it with a match instead.

Back in 1978, I bought an interesting book.

The authors took the 243 and the 6mm Rem, and loaded EVERY powder available, from the fastest pistol, to the slowest machine gun powder, and used a strain gauge (very new at the time) to measure the pressures and plot the pressure curves. It was way before it's time, and I think even now, it is still before it's time.

But, with the prior comments about "flash over" and pressure problems with large space in a case, I thought these curves might throw some light (and truth) on the subject.

If you look carefully at the curves, you can see that they are predictable.

So - it should be obvious that "flash over" is impossible, and all these analogies about sawdust and other stuff, is pure garbage and fabrications.

As far as throwing dust in an open fire?? Do you really want us to take you seriously??

Please give us a break from silliness!!

.

OK, so I have an applied fluid mechanics project to finish and final to prepare for, so I thought I would take a break and relax my brain a little on Predator Master's and I ran into Catshooter spanking somebody with facts that made my brain hurt more. I'm going back to Manning's equation, critical flow and hydraulic jump, at least I understand that.

SShooterZ

New member

Originally Posted By: tactical assaultOriginally Posted By: SShooterZSo what you're saying is use the cotton right?

NO, you missed the point again. You only use the cotton in the .223 cases, because it will flash over in the 5.56 cases. Don't worry, we will get you through it brother!!!

Damnit! I was so close!

NO, you missed the point again. You only use the cotton in the .223 cases, because it will flash over in the 5.56 cases. Don't worry, we will get you through it brother!!!

Damnit! I was so close!

Originally Posted By: 2muchgunOriginally Posted By: who me I thought the cotton helped keep the barrel clean. Kinda like swabbing out the carbon build up.

I really, really, hope that was meant as a joke

Yea, I meant it as a joke. I've loaded since 1974 and have known about polly-fill for a long time.

ninehorses

New member

CatShooter,

I think there is a typo in the second line(feet).

Otherwise a great post! I never understood what you so elequently explained, thank you!

I think there is a typo in the second line(feet).

Otherwise a great post! I never understood what you so elequently explained, thank you!

CatShooter

New member

Originally Posted By: ninehorsesCatShooter,

I think there is a typo in the second line(feet).

Otherwise a great post! I never understood what you so eloquently explained, thank you!

Thanks - I originally wrote it in feet, but went to inches and missed that one.

I think there is a typo in the second line(feet).

Otherwise a great post! I never understood what you so eloquently explained, thank you!

Thanks - I originally wrote it in feet, but went to inches and missed that one.

Ackman

New member

Originally Posted By: predyotevarmint

Primers affect the pressure generated by the cartridge. Changing from standard to magnum primers may substantially raise the maximum average pressure of the cartridge and indiscriminate changes are not recommended. The A-Square Company conducted pressure tests involving six different primers.

Ramshot did a primer test in their load guide edition one. With a .223 and Xterminator powder.......same brass, same 52Hornady hp, same seating depth, same charge weight......5 different primers. Lowest pressure was 44,880 psi, highest was 50,887 psi. But velocity at highest pressure was only 35fps faster than the lowest pressure.

Primers affect the pressure generated by the cartridge. Changing from standard to magnum primers may substantially raise the maximum average pressure of the cartridge and indiscriminate changes are not recommended. The A-Square Company conducted pressure tests involving six different primers.

Ramshot did a primer test in their load guide edition one. With a .223 and Xterminator powder.......same brass, same 52Hornady hp, same seating depth, same charge weight......5 different primers. Lowest pressure was 44,880 psi, highest was 50,887 psi. But velocity at highest pressure was only 35fps faster than the lowest pressure.