Quote:

The "bulge" that you will see just an 1/8" or so above the rim is not "case-head expansion" That is simply the case blowing out to fill the chamber. If the chamber were the exact size of the case, then the AR would not feed and function well. The chamber is somewhat larger than the new or resized case, and when the gun is fired, the case will expand to fill the chamber.

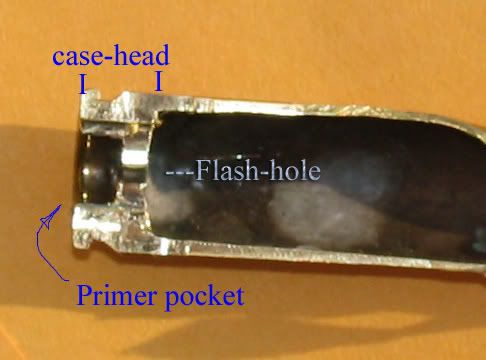

The "case-head" is the brass between the bottom end of the case, and the area that the powder is held. If you run a tooth-pick or some other object into the open mouth of the case and measure the depth and then compare it to the length of the case, you will find that there is an area of about .200" that is solid brass, except for the primer pocket and flash-hole. This area is the "case-head".

The case-head is the part of the brass that actually hangs out of the chamber, and is not supported by the chamber walls. In the case of higher than normal pressures, this area of the case will expand, but you will not be able to detect it by "looking" at it. You will have to measure the case-head before and after the shot with a micrometer.

Case head expansion is why primer pockets get loose. As the brass expands, the primer pocket expands with it, and eventually, the primer pocket will no longer hold the primer.

Edited to add this pictue:

Sorry for the poor quality photo, but I wanted to quickly get a photo up to show what I was talking about. You should be able to see the primer pocket and flash-hole. That area of thick brass is the case-head.

Very good thread and pics.

Have you got any pics of a cut-away case with the case beginning to separate or with the ring?